Products

What’s in store

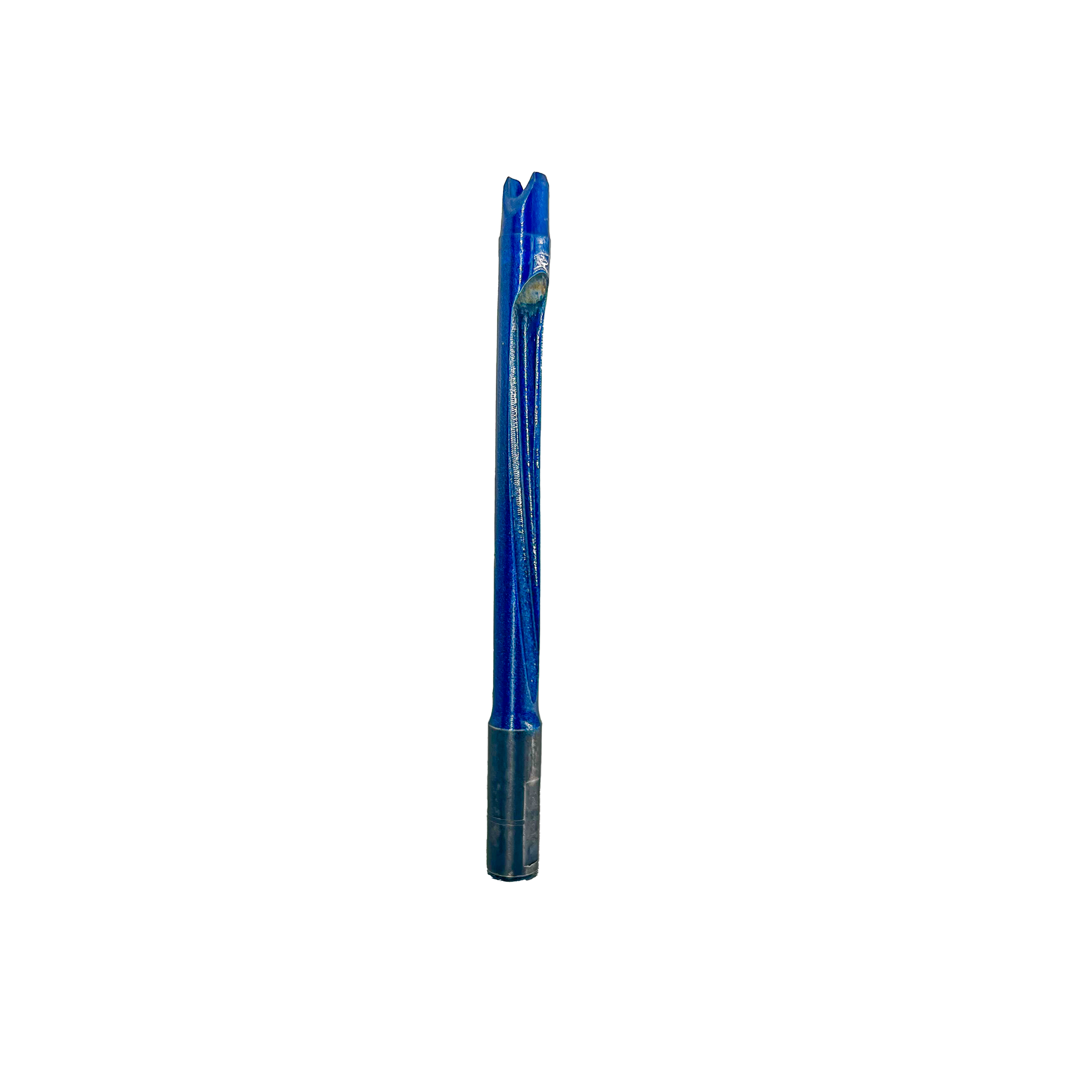

Selecting the Correct Tine

There are several important characteristics that one should keep in mind when deciding which JRM tine to order. Most JRM tines when compared to comparable OEM tines have a wall that is slightly thicker. This is necessary to provide the extra wear. In the design process it was decided that about 1/3 of the additional wall thickness would be distributed to the ID (Inside Diameter) and the remaining 2/3rds would go to the OD (Outside Diameter). These ratios vary slightly from tine to tine, but the principle is true of most JRM conventional tines. Because of the increased wall thickness and the resulting smaller core diameter (ID), it is often desirable to select a JRM tine that is listed as one size above the OEM tine you have historically used. For example, instead of a 1/2” OEM coring tine one might wish to use a 5/8” JRM tine.

In selecting the proper JRM tine you must first know the following:

- Maximum length tine that your machine will accept (this information should be available from the manufacturer.)

- The mount size (in inches) of the tine holder–you may also simply measure one of the tines you are presently using. (Most manufacturers offer several options when a new machine is purchased.)

- What is the soil composition you are likely to be encountering…if you are likely to encounter (rocks, push-up greens, or USGA spec soil). A top eject coring tine is structurally stronger than a side-eject coring tine.

- Is your aerification machine setup with the proper timing?

- Carefully check the ID of the tine you are considering since this will be the core size with coring tines.

Selecting the correct INFINITY® DURANIUM-24 Reel

Follow the instructions in the JRM Parts catalog and/or Reels Pamphlet to select the correct reels per set.

Bearings kits are available for purchase separately on all JRM INFINITY® DURANIUM-24 Reels.

In selecting the proper JRM reel you must first know the following:

- Toro® reels: Verify your cutting unit model number (5-digit number on top of the cutting unit) to ensure the proper reel is selected.

- Toro® reels: Bearings come inserted on the shaft on all new style Toro® reels (5RTG112100, 5RTG142100, 5RTF085210, 5RTF115610, 5RTF085510)

- John Deere® reels: All reels are made to fit the quick adjust cutting units (QA5-5” reels and QA7-7” reels).

- Jacobsen® reels: These reels have left-hand and right-hand drive options.

Selecting your DURANIUM-801® Bedknife

Extended-Cut: Designed to position the cutting-edge further dead center on the reel allowing for a less-aggressive angle to the ground minimizing the chances of bruising, dragging, and scuffing.

Ultra-Cut: The bottom face angles are cut back to the screws to allow for maximum drag clearance to avoid bruising, dragging, and scuffing. Feature the same cutting-edge thickness as a Micro-Cut, but can provide the flexibility to cut as low as .070” due to the extended bottom face angles

Elite Super Thin (Pebble Beach): The thinnest bedknife on the market with a .050” cutting-edge height. Not designed for everyday use but for special occasions to achieve the cleanest and lowest possible cut.

Select according to your cutting height.

These will not cut lower than the minimum cutting-edge height listed.

- Standard Low cut: .135” & above

- Tournament-cut: .115” & above

- Micro-Cut/Super Tournament: .098” & above

- High-cut: .175” & above

Check out our other products including JRM merchandise

Delve into our

Featured Turfgrass Maintenance Products

Discover the future of turf care with JRM’s premier products – setting the bar higher with each innovation.